Label Slitting and Inspection Machine

Working principle of flexographic label printing machine

Flexographic label printing presses use fluid inks with high fluidity. The ink is transferred from the ink fountain roller to the anilox roller, which then transfers the ink to the image area of the printing plate. The impression cylinder then applies printing pressure to transfer the ink from the printing plate to the substrate. Finally, the printing process is completed after drying.

Main features of flexographic label printing machine

Stable and Precise Printing:

For example, the F2 series flexographic printing press from Donghang Printing Technology features a plate roller supported by a shoulder-mounted cam and secured with a locking hook, ensuring stable and reliable operation. It effectively overcomes vibration problems caused by plate seam impact and has a pre-registration function, ensuring accurate registration and delivering qualified prints even during acceleration or deceleration.

Easy and Efficient Operation:

Flexographic printing presses have a relatively simple structure. Their anilox roller inking method results in a short ink path and rapid ink supply control response, allowing printing workers to quickly learn and operate the machine, reducing training and setup time.

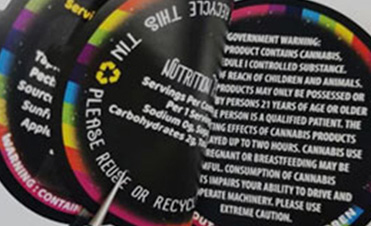

Wide Substrate Adaptability:

Printing can be performed on a variety of materials, including coated paper, cardstock, self-adhesive labels, non-woven fabrics, BOPP, and PET plastic film.

Excellent Environmental Performance:

It can use pollution-free, fast-drying water-based inks or UV inks, causing no environmental pollution and posing no harm to human health, meeting the environmental and sustainable development requirements of the modern printing industry.